Washable labels

In the process of sustainability and recycling, brands are continually striving to make their packaging greener. Washable labels are a notable and revolutionary trend within the packaging industry. But what are washable labels exactly, and how do they improve recycling processes?

What are washable labels?

washable labels are designed to be easily removed from packaging. This leads to a more

efficient and better recycling process. The key to this technology lies in the special

adhesive. The label can be removed by the waste sorter by washing the packaging in an

alkaline solution between 65°C and 80°C. It is important to note that washable adhesives

are not intended for removing labels in a dishwasher.

Besides the recycling

benefits, the appearance of washable labels is better than that of traditional wet glue

labels, which are still widely used in recycling processes.

How does the washable process work?

Currently, there are two major recycling streams that use washable labels: PET and

glass. Both streams use a specific adhesive.

PET packaging is shredded after

collection. Glass is recycled using the washable process without damaging the glass.

After collection, the packaging is washed in a warm alkaline solution between 65°C and

80°C. During this process, the labels float to the surface and carry away adhesive

residues and ink. The result of the process is pure PET, suitable for making new PET

packaging, or glass that can be refilled.

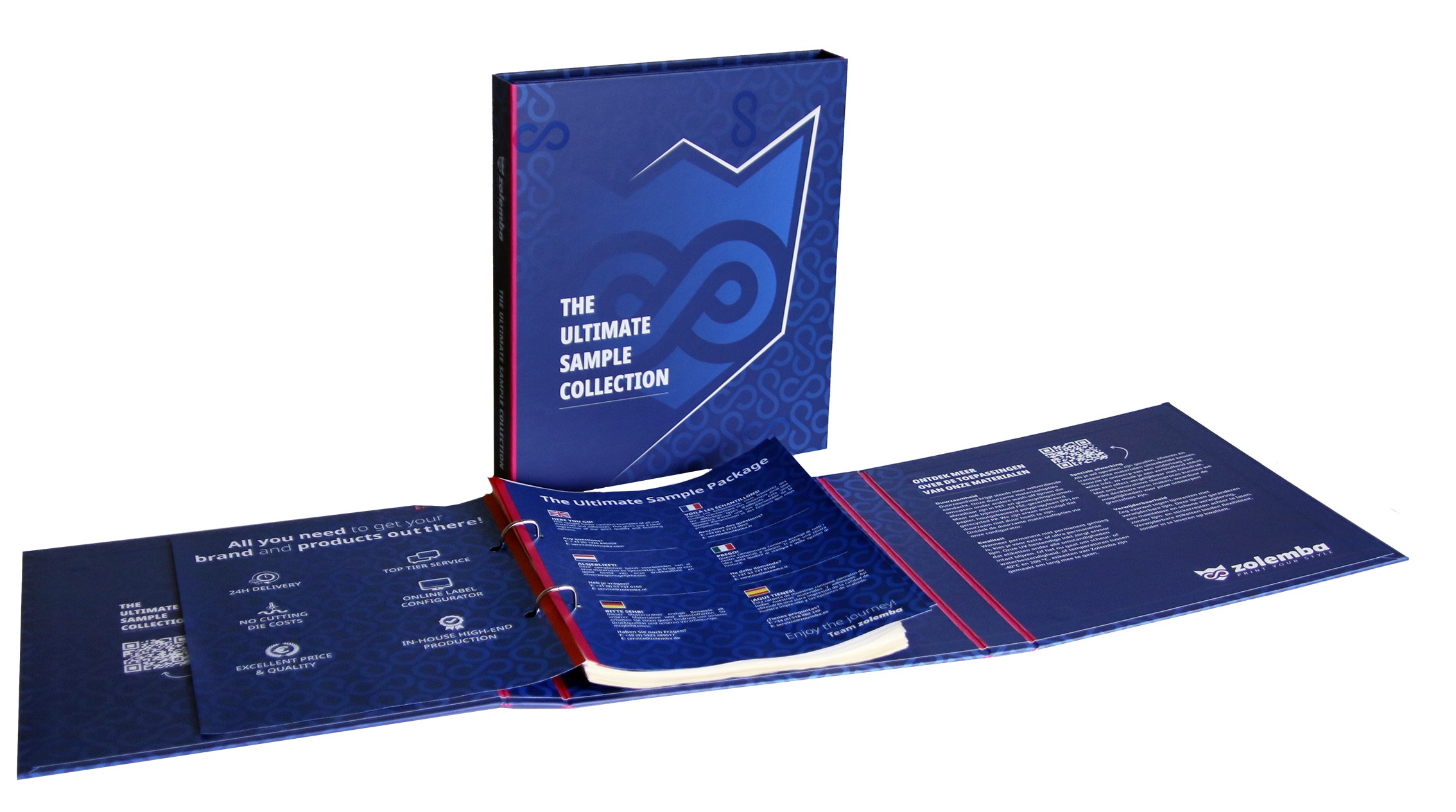

Order washable labels from Zolemba

Zolemba offers two types of washable labels in its range. These are paper labels with RP30W adhesive. This material is approved for use on the Bruin Nederlandse Retourfles (BNR) as a beer label. The PP labels with washbale adhesive have RP85W glue and are suitable for use in industrial recycling processes. Want to know more about washable labels? Feel free to contact us at service@zolemba.nl for advice.

Exclusive Offers and Free Tips!

Stay informed and never miss out on offers, handy tips, or free templates.

Thank you! You have successfully subscribed to our newsletter.

.png)